FLAIR is honoured to announce that 2 of its technological innovations have won the TechConnect 2023 Innovation Awards. TechConnect 2023 has attracted more than 170 aplications from more than 90 organisations around the world. This is the first time FLAIR participated in the contest.

Looking forward, FLAIR will continue its dedication to industrial AI & robotics innovations and its coordination with industries to address industry pain points on the path of new industrialisation.

FLAIR’s winning innovations at TechConnect 2023:

ARGUS – Anomaly Recognition Graphical Universal System ARGUS is an AI defect inspection system with a 3D camera on a robot arm designed for quick deployment in various production lines and products. Minimal data is required for AI training.

ARGUS is an AI defect inspection system with a 3D camera on a robot arm designed for quick deployment in various production lines and products. Minimal data is required for AI training.

Automotive parts bear complex structures and the characteristics of high-mix low-volume. The existing detection technologies in the market are limited as experienced professionals are required during data collection to set the angular position; it is also difficult to cover the entire surface.

The name ARGUS came from Argus, the many-eyed giant in Greek mythology, who is said to be able to watch from all directions with his more-than-100 eyes even during sleep. At FLAIR, ARGUS steps further by not only inspecting complex objects from all-around views with nimble “hands” (collaborative robotics) but also detecting tiny defects on a surface with intelligent “eyes” (high-resolution cameras). Then, the smart “AI brain” of ARGUS finds the best views of the products autonomously and explores unknown flaws by unsupervised learning from limited good products to achieve smart quality inspection of automotive parts.

ARGUS is jointly developed by research teams from FLAIR, HKPC and Pro-Technic Machinery Ltd. with patents in the Mainland and HKSAR. The teams will continuously improve the detection accuracy, thereby improving product quality, saving labour costs, and accelerating product flow.

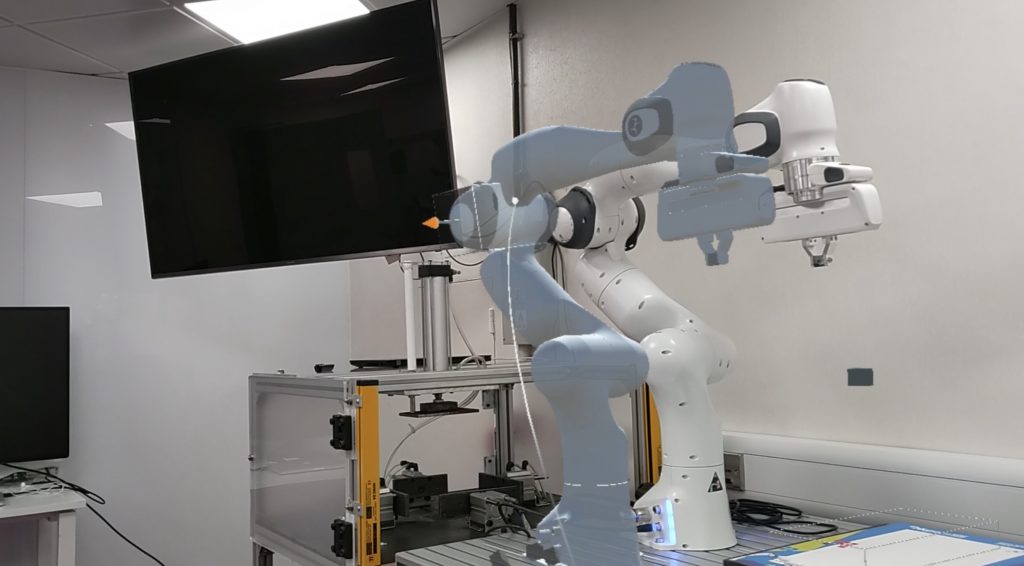

Interactive Control System for Robot Manipulation with AR Technology

The innovation involves intuitive interaction through AR glass so that the human operator can monitor as well as control the industrial robot arm both on-site and remotely. Robotic tasks can be demonstrated by humans in the augmented reality environment and the skill can be transferred directly to the robot arm for task execution.

There is invariably a trade-off between safety and efficiency for collaborative robots (cobots) in human-robot collaborations. The innovation provides a new complementary framework for human-robot collaboration that balances the safety of humans and the efficiency of robots. The robot carries out given tasks using a vision-based adaptive controller, and the human operator collaborates with the robot in the null space. Additionally, the robot can simultaneously learn the expert's demonstration in task space and null space beforehand with dynamic movement primitives (DMP). Human demonstration and involvement are enabled via augmented reality (AR) devices, achieving simple and efficient data collection from demonstration.

Our technology unlocks a new possibility where work can be done inside a remote environment and with more intuitive controls, allowing workers to create perfect results even with lower understanding of robotic controls.

The innovation is jointly developed by research teams from FLAIR and Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology which is jointly found by HKPC, Department of Automation, Tsinghua University and Research Institute of Tsinghua, Peral River Delta. The technology simplifies the automation process for factories and stations, promoting the trend to a larger extent. In addition, the system allows the human operator without expertise in robot programming to interact with the industrial robot and teach it automated tasks intuitively faster than traditional robot programming solutions.

For the complete awardee list, please visit: https://www.techconnectworld.com/World2023/participate/innovation/awards.html